Tidsfordriv

Litt mer om kabler

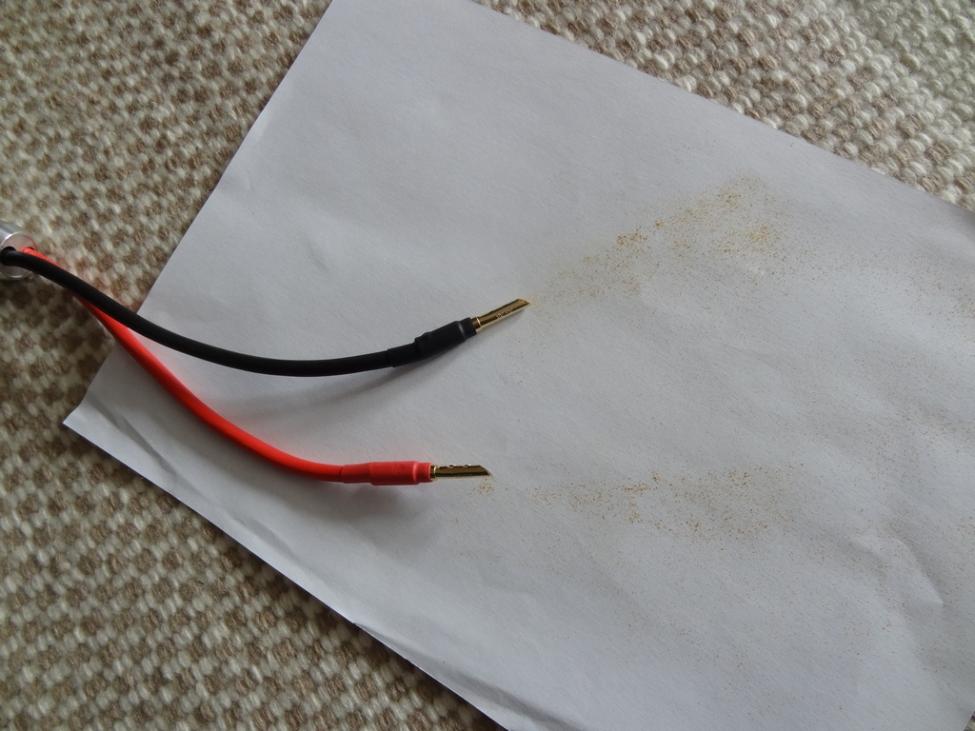

Testing Cables with High Voltage

Hipot Testing FAQ

High Voltage Testing Videos

Introduction to Hipot Testing

A "garden hose" analogy shows how hipot testing works and answers these questions:

Play Having trouble viewing this video? Click

here.

Understanding Hipot Cable Testing Errors

Learn more about these errors:

- Overcurrent

- Had Leakage

- Dielectric Failure

Play Having trouble viewing this video? Click

here.

What is "hipot" testing?

Many people are familiar with a continuity test. A continuity test checks for "good connections,” meaning current will flow from one point to its destination point. If current flows easily enough then the points are connected. Many people are less familiar with a hipot test. "Hipot" is short for high potential (high voltage).

A hipot test checks for "good isolation." A hipot test checks that no current flows between points where there should be no current. In some ways a hipot test is the opposite of a continuity test.

Continuity Test: "Makes sure current flows easily from one point to another point."

Hipot Test: "Makes sure current does not flow between points where there should be no flow (using high voltage to ensure current does not flow)."

A hipot test takes two conductors that should be isolated and applies a very high voltage between the conductors. The current that flows is watched. If too much current flows the points are not well isolated and they fail the test.

back to top Why high voltage test?

A hipot test checks for good isolation between the parts of a circuit. Having good isolation helps to guarantee the safety and quality of electrical circuits. Hipot tests are helpful in finding

- nicked or crushed insulation

- stray wire strands or braided shielding

- conductive or corrosive contaminants around the conductors

- terminal spacing problems

- tolerance errors in IDC cables

All of these conditions might cause a device to fail.

back to top What kinds of high voltage tests are there?

There are three common high voltage tests.

- Dielectric Breakdown Test

- Dielectric Withstanding Test

- Insulation Resistance Test

back to top What is "dielectric breakdown testing?"

Dielectric breakdown testing answers the question, "How much voltage can I apply between the wires before the insulation fails?" The test increases the voltage until the current increases. This method finds the highest voltage the cable can stand before it fails. Once the cable fails, it is usually damaged or destroyed.

back to top What is "dielectric withstand testing" (DW)?

Dielectric withstand testing answers the question, "Will this cable withstand a required voltage for a required time?" The test applies the required voltage for the determined amount of time and watches for current flow. Ideally, no current flows and the cable is not harmed.

back to top What is "insulation resistance testing" (IR)?

Insulation resistance testing tries to answer the question, "Is the resistance of the insulation high enough?" The test applies a voltage and measures the current. It then calculates the insulation resistance using Ohm's Law (R = V/I).

back to top How do these "hipot" tests affect quality?

All of these tests are tools used to understand how a cable will perform and to monitor any changes in the cable's performance.

Dielectric Breakdown testing is used in product design and qualification stages. It helps establish the maximum voltage of the design. It can also be used on a random sample basis to verify that the maximum voltage is not changing. Dielectric breakdown testing may be required during the development of assemblies used in critical applications.

Many test specifications require a Dielectric Withstand test on every cable produced. The test is usually performed at about 75% of the typical breakdown voltage and is done as a safety net. The test is sensitive to arcs or corona so it often finds terminal spacing problems, over-mold problems, tolerance errors in IDC cables, or any problem that might produce arcs. This test doesn't significantly degrade the cable.

The Insulation Resistance test is typically done on every cable tested and usually done at 300 to 500 Vdc with 100 to 500 MegaOhms resistance. The test is very sensitive to contamination in the assembly process. Solder flux, oils, mold release agents, and skin oil can cause problems. This test excels at identifying insulation that will conduct in the presence of moisture. Doing this test on every cable allows you to detect contamination changes in the manufacturing process.

back to top With all the high voltage being used, what about safety?

Products being designed today should comply with product safety regulations. Some of these regulations reduce the chance of receiving harmful electrical shock. During a hipot test you may be at some risk. The risk can be reduced by following the manufacturer's instructions. When it comes to hipot charge, energy, and voltage, select the "safest" machine that will meet your cable testing requirements.

To minimize your risk of injury from electrical shock make sure your hipot equipment follows these guidelines:

- The total charge you can receive in a shock should not exceed 45 uC.

- The total hipot energy should not exceed 350 mJ.

- The total current should not exceed 5 mA peak (3.5 mA rms)

- The fault current should not stay on longer than 10 mS.

- If the tester doesn't meet these requirements then make sure it has a safety interlock system that guarantees you cannot contact the cable while it is being hipot tested.

These guidelines come from the test standard EN61010-1, Safety requirements for electrical equipment for measurement, control and laboratory use, April 1993,

CENELEC. Over the last decade many of the safety regulations have been harmonized (standardized) and EN61010-1 is similar to UL 61010A-1 (formerly UL3101-1).

While you are testing cables there are several things you can do to reduce the risk even more:

- Verify the correct operation of the safety circuits in the equipment every time you calibrate it.

- Follow all of the manufacturer's instructions and safety guidelines.

- Don't touch the cable during hipot testing.

- Allow the hipot testing to complete before removing the cable.

- Wear insulating gloves.

- If you have any health condition that can be aggravated by being startled then don't use the equipment.

- Don't allow children to use the equipment.

- If you have any electronic implants then don't use the equipment.

back to top Where is the high voltage applied?

To understand how hipot testing works you'll need to understand where to connect the high voltage supply. Hipot testers usually connect one side of the supply to safety ground (Earth ground). The other side of the supply is connected to the conductor being hipoted. With the supply connected like this there are two places a given conductor can be connected: high voltage or ground.

When you have more than two contacts to be hipot tested, connect one contact to high voltage and connect all other contacts to ground. Testing a contact in this fashion makes sure it is isolated from all other contacts.

What happens when you test something more complicated than just contacts? A series of contacts that are connected with wires, resistors, capacitors, diodes, and other components is called a "network" of connections (or "net"). To hipot test a net, you connect all of the contacts in the net to high voltage and connect all other contacts in the device to ground. For example, if you have a wire that connects two pins, the high voltage will be simultaneously apply to both of those pins and the entire wire will be raised in voltage. All other wires and pins will be held at ground. If you have a resistor that connects two pins, both pins are raised in voltage and the voltage drop across the resistor is always zero. The entire resistor is raised in voltage. In short, all pins of a component see the same voltage at all times. Applying the voltage in this fashion makes sure the body of the component is isolated from the rest of the device.

back to top Where is the current measured?

During the hipot test the current that flows out of the high voltage supply is measured.

back to top What causes current to flow through an insulator?

Insulation "does not conduct." But if you use enough voltage even the best of insulations will allow some current to flow. There are several reasons current will flow through insulation during a hipot test. Resistance, capacitance, arcs, electrochemical effects, and corona are all effects that describe current flow. All of these effects added together during a hipot test shape the results.

back to top Which Cirris testers are capable of high voltage testing?

Cirris manufactures industry-leading high voltage cable testers. For information on these analyzers visit our

cable testers product page.

"Breaking in" a cable has everything to do with the insulation - not the wire itself. The insulation (or dielectric) will absorb energy from the conductor when a current is flowing (i.e. when music is playing). This energy-absorption causes the dielectric's molecules to re-arrange themselves from a random order into a uniform order. When the molecules have been rearranged, the dielectric will absorb less energy & consequently cause less distortion. The cable is now said to be "broken in" and sound quality is improved. To prove it, simply take 2 pairs of the same cable - one broken in, one new, and compare in the same system.

2.1.1.4 Tap

Det vil alltid oppstå tap i en kabel som leder elektrisk energi, både ohmske, induktive og dielektriske tap. Denne tapte energien vil omgjøres til varme, og som beskrevet tidligere svekkes lederens overføringsevne ved høy temperatur. Varmen må derfor ledes ut av kabelen. Det er også viktig at isolasjonen ikke overopphetes. Det er isolasjonstypen som avgjør hvilken driftstemperatur vi kan ha på lederen. PEX skal ikke utsettes for temperaturer over 90 °C. Ved denne temperaturen svekkes de dielektriske egenskapene og det kan oppstå kabelhavari. Ved en eventuell kortslutning i PEX-kabel er maksimal tillatt ledertemperatur 250 grader (i ett sekund), og maksimal strømtetthet er forskjellig for de ulike materialene. Kobber har en maksimal tillatt strømtetthet på 140 [A/mm2], mens aluminium har 90 [A/mm2].

2.1.2 Halvleder

En halvleder er simpelthen ”forurenset” isolasjon, i vårt tilfelle vil det si forurenset PEX. PEX’en tilsettes karbon, noe som gjør at den beholder sine termiske egenskaper, men oppnår andre elektriske egenskaper. Isolasjonen og halvlederen er dermed like, med unntak av den elektriske ledningsevnen som er bedre i halvlederen. Halvledermaterialet legges både på innsiden og utsiden av kabelisolasjonen. Hensikten med å legge på halvledende materiale er å få en jevn elektrisk feltfordeling, og forhindre utladning i isolasjonen. I tillegg bidrar halvlederen til å jevne ut overgangene mellom leder, isolasjon og skjerm.

2.1.3 Isolasjon

Egenskapene til et isolerende materiale kjennetegnes av at bindingsstrukturen er jonisk eller kovalent, eller en blanding av de to. Ioner og elektroner er på ingen måte frie som i metaller, de er tett sammenbundet.

PEX er et svært vanlig isolasjonsmateriale innenfor kabelteknikk. PEX er kryssbundet Polyetylen, med høy tetthet. Bindinger mellom makromolekylene i Polyetylenet formes slik at det dannes broer mellom molekylene, derav ”kryssbinding”. Resultatet blir molekyler som tåler ekstreme forhold, som for eksempel høye temperaturer, kjemiske angrep og også deformasjon. Materialet gir svært god elektrisk isolasjon, med høy ledningsmotstand og lite dielektrisk tap. Ved 20 °C er den dielektriske konstanten 2.3 og gjennomslagsspenningen på 60-90 kV per mm.

Det stilles imidlertid også visse krav til kabler som PEX-isoleres, spesielt til bøyeradius. Under normale forhold bør ikke en PEX-kabel ha mindre bøyeradius enn 20-25 ganger sin egen ytre radius. Ved montering under lave temperaturer (<-10 °C) bør kabelen varmes opp før den bøyes.

2.1.3.1 Kvalitet på PEX

Kvaliteten til isolasjonsmaterialet avhenger av renhetsgraden, dersom det forekommer urenheter i materialet vil sjansen øke for elektronforflytning over energigapet, og dermed også svikt i isolasjonen. Den dielektriske styrken til et materiale defineres som: Spenning per enhet som skal til for å fremkalle et sammenbrudd. Ved store tverrsnitt vil strømmen imidlertid konsentrere seg i ytterkant av lederen, denne strømfortrengningen skyldes det indre feltet i lederen, og kalles skinneffekt. Utbytte av økt ledertverrsnitt vil da forsvinne siden strømmen får mindre areal å bevege seg på. Dette kan delvis kompenseres for ved å isolere enkelttrådene i lederen (Litzkordeller). Dette er en meget dyr løsning som ikke kan forsvares mot det tapte ledertverrsnittet.Naboeffekt er i likhet med skinneffekt en form for strømfortrengning. Forskjellen på de to er at naboeffekten skyldes felt fra andre nærliggende strømførende ledere, og ikke eget indre felt. Vi tar utgangspunkt i at kabelens skjerm er jordet i begge ender. For trefase spiller faserekkefølgen og plasseringen av disse i forhold til hverandre en stor rolle. I juli 2006 gav Ferkal, Poloujadov og Dorison ut en rapport som tok for seg naboeffekt og virvelstrømstap i isolerte kabler. Rapporten deres innholder mye avansert matematikk som høyskolelektor Kent Ryne har hjulpet oss med. Dette kapittelet baserer seg på deres rapport.

RADIATION EFFECTS DESIGN HANDBOOK Section 3. Electrical ... transistors,

diodes, in sensitivity to radiation. Consideration of ... ure of an

insulator or dielectric will adversely

affect its electrical char- acteristics. ... materials,

wire and

cable insulation, encapsulating compounds, connectors and terminals, and ...

http://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19710020300.pdf