Roboter var vel på høyde med mennesker mer eller mindre på 80-taller i produksjonen og nøyaktighet, men tidligere så var håndverk mye bedre fra mennesker. Mennesker ble lett passert på 90-tallet og det er en grunn til at ting er såpass små idag med nøyaktigheten til roboter og produksjon på nano meter nivå, prøv å få til det med 1000 enheter om dagen som et menneske, eller bare en i året for den saks skyld.. Ta f.eks. en Intel CPU mtp. nøyaktighet som blir å ligge på 7 nano meter på ny gen som slippes i år, med den komplekse arkitekturen der så er det umulig å lage for hånd. Det finnes noen håndlagde CPUer selv idag, de kan sammenlignes med 386/486 i ytelse og de er fysisk gedigne i størrelse.

Finnes det noen "tweaks" som er så "over the top" at ingen går på de?

- Trådstarter danelectro

- Startdato

Diskusjonstråd Se tråd i gallerivisning

-

Interesserte kan lese mer her: https://audioxpress.com/article/voi...istics-of-adhesive-joints-and-cone-treatments

Dette påvirker faktisk lyden, og det er ingen ting som taler for at håndarbeid er løsningen.

Linken fungerer ikke.Interesserte kan lese mer her: https://audioxpress.com/article/voi...istics-of-adhesive-joints-and-cone-treatments

Dette påvirker faktisk lyden, og det er ingen ting som taler for at håndarbeid er løsningen.

Men matching av håndlagde drivere kan jeg tenke meg at det "dreier seg om"? Det er vel en vanskelig nok øvelse.Testet den nå, den fungerer helt fint her. Kan siden ha vært nede et øyeblikk?

Det handler om hvordan valg av lim osv påvirker lyden i en ferdig driver. Det er myntet sånne nisser som meg som beskjeftiger meg med produksjon av drivere og har måttet begynne å tenke på detaljene

Den var nok nede litt ja, funker nå!Testet den nå, den fungerer helt fint her. Kan siden ha vært nede et øyeblikk?

Det handler om hvordan valg av lim osv påvirker lyden i en ferdig driver. Det er myntet sånne nisser som meg som beskjeftiger meg med produksjon av drivere og har måttet begynne å tenke på detaljene- Ble medlem

- 23.03.2006

- Innlegg

- 20.939

- Antall liker

- 11.613

Disse skribentene skriver vel akkurat det leserne ønsker å lese. Morro å kunne ramse opp "tekniske" uttrykk for de uvitende som ikke leser magasinene, får masse kred da....Har samme hvite IKEAskålen kanskje jeg skal begynne med å produsere haitalere... . For øvrig joda de fleste Haifai sjornalister har teknisk kunnskap på nivå med min bestemor, husmorskolen. Men glødende engasjement for "saken", for all del, kompetanse i form av - har hørt mye dyrt stash. Og litt oppblåst selvbilde. Kritiske spyrgesmål - gløm det.

"For i haiendland der kan alt gå an, der er de like ... alle mann"Hifi-magasiner må en vel først og fremst ta som god underholdning... Men det er helt greit det.

Som man sikkert har lagt merke til gjør jeg mye rart som DIY. Det er veldig vanskelig å få til stort bedre toleranser enn +/- 0,5 mm når jeg gjør ting for hånd, på en god dag kanskje +/- 0,2 mm. «Ekstrem presisjon» - glem det. Da behøver man egnet maskineri, men det koster jo en hel del mer penger enn hva DIY-ere har disponibelt.Jeg hadde nok trodd at når det angår roboter og nøyaktighet…. men hva vet jeg?

As one of the most advanced and precise equipment in the world, a photolithography scanner is able to fabricate nanometer-scale devices on a chip. To realize such a small dimension, the optical system is the fundamental, but the mechanical system often becomes the bottleneck. In the photolithography, the exposure is a dynamic process. The accuracy and precision of the movement are determined by the mechanical system, which is even more difficult to control compared with the optical system. In the mechanical system, there are four crucial components: the reticle and wafer stages, the linear motor, the metrology system, and the control system. They work together to secure the reticle and substrate locating at the correct position, which determines the overlay and alignment performance in the lithography. In this paper, the principles of these components are reviewed, and the development history of the mechanical system is introduced.

FPA-6300ES6a | Canon Global

This page provides information on High Resolution / High Productivity KrF Scanner "FPA-6300ES6a."global.canon

Den er ca hundre tusen ganger stødigere på labben enn meg, og jeg liker jo å tenke at jeg ikke er den aller mest klønete selv heller.To minimize overlay misalignment & intrafield distortion during exposure, advanced stage vibration & synchronous control technologies were adopted in the FPA-6300ES6a. The alignment scope was also improved in order to measure the alignment marks on a wafer more accurately.

Furthermore, by accurately controlling the temperature of the exposure area and the reticle area, **industry-leading Mix & Match overlay accuracy of ≤ 5nm has been realized.

Saken er at «high-end»-produsenter er glorifisert DIY uten kapital til å investere i presisjonsutstyr. Da blir det en dyd av nødvendighet for dem å hausse opp «håndlagd» som om det skulle være noe positivt. I virkeligheten vil jeg tro at masseprodusert PA-utstyr fra profesjonelle aktører som BMS og 18sound har langt bedre toleranser og mindre eksemplarvariasjon.Sist redigert:Peanuts mot håndverket high end bransjen som kjent.

Audiopressen gjør nok ikke noe annet enn å gjengi hva produsenter legger ut reklamemessig. De gjør sjeldent til aldri noen innsats for å verifisere påstandene og sannhetsgehalten i de.Sist redigert:Mye placebomassasje der.Fra et annet hififorum;

Kanskje ikke i kategorien tweak akkurat dette - men handler litt om hvordan folk TROR at hifi er Rocket Science og så utrolig komplekst/annerledes så ingen andre industrier klarer å forholde seg til det.... (gjengitt med velvillig tillatelse fra et høyt profilert medlem på HFS som foretrekker å være anonym av frykt for represalier)

som foretrekker å være anonym av frykt for represalier)

Jaja,,, - de kan le og more dem, de... men gråten tar meg....Egentlig et under at www virker i det hele tatt.

Vis vedlegget 969195 Vis vedlegget 969196 Vis vedlegget 969197

Folk som tror at frames (L2 der svitsjer fungerer) er audio, hmmm…

Snakeoil leverandører har ødelagt mye.

Idiotene kommer til å ta over verden en dag! Å starte med audiofile switcher i stamnettet er nok en god start på verdensherredømme! De har ikke hørt om spanning tree og aner heller ikke hva L2 og L3 er for noe og resten av lagene og hvordan dette samspiller, de kan vel i beste fall relatere til hvordan en hub kanskje fungerer..Egentlig et under at www virker i det hele tatt.

Vis vedlegget 969195 Vis vedlegget 969196 Vis vedlegget 969197

At de vet hva en hub er ja, hva den gjør eller hvordan den fungerer definitivt NEI!Idiotene kommer til å ta over verden en dag! Å starte med audiofile switcher i stamnettet er nok en god start på verdensherredømme! De har ikke hørt om spanning tree og aner heller ikke hva L2 og L3 er for noe og resten av lagene og hvordan dette samspiller, de kan vel i beste fall relatere til hvordan en hub kanskje fungerer..

Når du tror at du kan ha to svitjser eller fire i parallel eller hva f.n de gjør, og tror at det låter bedre, da er det ingen grenser eller håp.

Det finnes ingen audio i det digitale domene, det oppstår i grenseland der digital og analog møtes, en DAC.

Men men, det er folk som tror på mye rart ellers, den siste idiot er definitivt ikke født enda.- Ble medlem

- 21.06.2016

- Innlegg

- 693

- Antall liker

- 866

Her er resultatet av å skrive inn ordet idiot i AI bildegeneratoren til stablediffusionweb com

og wikipedia...

https://no.wikipedia.org/wiki/Idiot- Ble medlem

- 12.02.2016

- Innlegg

- 2.124

- Antall liker

- 1.287

cdspiller og prosessor €30kVedlegg

-

246.5 KB Visninger: 260

-

154.7 KB Visninger: 217

- Ble medlem

- 21.06.2016

- Innlegg

- 693

- Antall liker

- 866

Den Cd spillern får vel ikke bare problemer med WAF…cdspiller og prosessor €30k

Jeg hadde en gang et par Holfi Sonair som trengte en liten touch up. Tok de til en billakkerer og jammen viste deg seg ikke at de var langt flinkere til å lakkere enn Holfi.Fra et annet hififorum;

Kanskje ikke i kategorien tweak akkurat dette - men handler litt om hvordan folk TROR at hifi er Rocket Science og så utrolig komplekst/annerledes så ingen andre industrier klarer å forholde seg til det.... (gjengitt med velvillig tillatelse fra et høyt profilert medlem på HFS som foretrekker å være anonym av frykt for represalier)

som foretrekker å være anonym av frykt for represalier)

Vis vedlegget 969205

Influx?...to in effect generate a contineous lower impedance path for the cosmic ionic particle influx to follow.

Influx

www.influxnet.com

www.influxnet.com

Influx er en Jesus-sentrert bevegelse

av disipler og menigheter som

bringer evangeliet igjennom nasjonene og

tilbake til Jerusalem.- Ble medlem

- 29.10.2016

- Innlegg

- 10.604

- Antall liker

- 28.398

- Sted

- Hjortshøj, Danmark.

- Torget vurderinger

- 2

Enig.....Jeez, for et firma.

Men mht finansstatus etter et (nesten) helt liv, må man jo erkjenne, att man har vært i helt feil bransje

det meste av livet

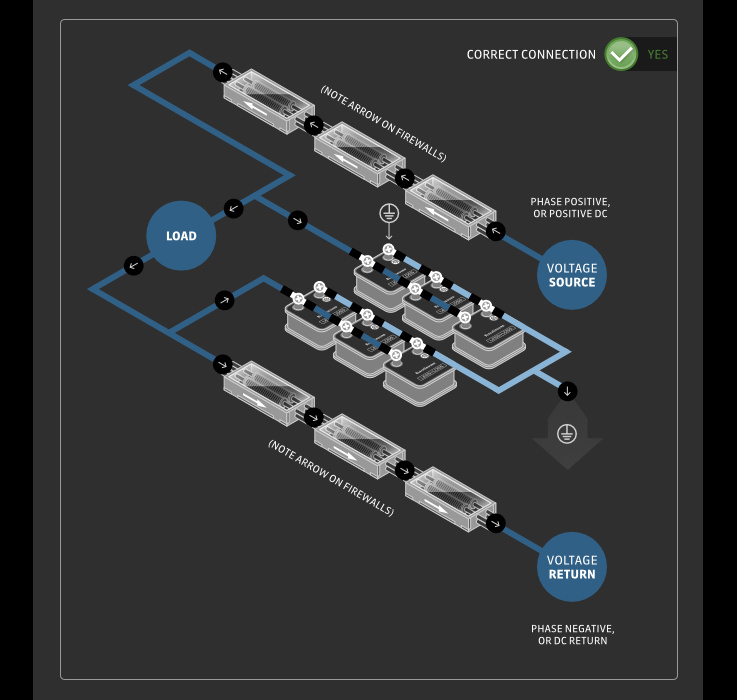

Her er de dog ganske ærlige om produktes værdiløshed, som vises af deres egne tegninger. BlackGround er en dims

Her er de dog ganske ærlige om produktes værdiløshed, som vises af deres egne tegninger. BlackGround er en dims

der spiser al støj uden der er DC gennemgang. Så den må være kapasitivt virkende.

Her vist som støjspiser i et af deres komplette line filter opstilling:

Altså BlackGround afkobler al støj til "jord". Så langt så godt. Men nu går det da helt galt:

Her anvendes de som en besværgelse i forbindelse med et LF-signal.

Derfor må vi konkludere at "dimsen" burde være fuldstændig virkningsløs i området fra nogle få Hz til ihvertfald 20KHz...

BlackGround dimsen indeholder nok en skefuld kattegrus, eller en kondensator på nogle få pF...Opphavet til mye rart:

World of Hi-Fi – Danmarks største Hi-Fi arkiv (worldofhifi.dk)Det virket jo veldig uskyldig før da, nesten som practical jokes

Hiv alufolie mellom sidene i noen bøker

sag av kanten på bordet (eller en arm)

ring med noen klokker i hvert hjørne av lytterommetJokes er det da fortsatt nok og mere av... bare ikke særlig praktiske...

Mine forrige høyttalere var custom DIY gjord av ekte håndverkere, lakkert på bilverksted, lakkeringen alene økt kostprisen fra 12 til 18 tusen, fikk solgt den for 8.. gøy erfaring med TQWT og rør da. poenget er et billakkeringem gjorde at ingen kunne se det var DIY og. I hvitt! Som er meget avslørendeFra et annet hififorum;

Kanskje ikke i kategorien tweak akkurat dette - men handler litt om hvordan folk TROR at hifi er Rocket Science og så utrolig komplekst/annerledes så ingen andre industrier klarer å forholde seg til det.... (gjengitt med velvillig tillatelse fra et høyt profilert medlem på HFS som foretrekker å være anonym av frykt for represalier)

som foretrekker å være anonym av frykt for represalier)

Vis vedlegget 969205

Får meg til å lure på hvordan en audiofil ser ut…Her er resultatet av å skrive inn ordet idiot i AI bildegeneratoren til stablediffusionweb com

Vis vedlegget 969237

og wikipedia...

https://no.wikipedia.org/wiki/Idiot

Når jeg skriver idiot får jeg dette..

- Ble medlem

- 12.02.2016

- Innlegg

- 2.124

- Antall liker

- 1.287

Gemini 3.0

Meet the iFi audio Mercury3.0. Maximum signal transfer. Minimum interference. Whatever language you listen to music in, we know you prefer it as interferences free as possible. You need the Gemini3.0 dual-headed cable. In most mass-produced USB cables, the signal and power cables are normally... ifi-audio.com

Fra et gammelt Svensk underholdnings program i TV: "till de danska tittarna kan vi säga att det går lika bra med selleri"

ifi-audio.com

Fra et gammelt Svensk underholdnings program i TV: "till de danska tittarna kan vi säga att det går lika bra med selleri"

-ellers prøv med hvidløg..!sMB-Q370 – SOtM – English

www.sotm-audio.com

www.sotm-audio.com

You would simply get clear improvements in every aspect of the music including the background, texture, tension, resolution, and location in space of the music with the sMB-Q370 designed exclusively for audio. If you close your eyes and listen to the music, you will feel as if it is the beginning of a new world with the subtle reverberation of instruments resonating in the dark.

Her er det bare å holde på trusa så den ikke ramler av…

Nope. Begriper ikke poenget med det der. Forstår ikke hvorfor separate kabler for (DC) power og (digitalt) signal liksom skulle gjøre noe som helst nyttig, aller minst når jeg ser hvor ettertrykkelig eventuelle jordsløyfer er koblet. Fem meter luft med wifi gjennom blir et mye bedre galvanisk skille.SOTM driver med mye rart. Siste generasjon av dedikert USB kort for pcen din.

tX-USBx10G – SOtM – English

www.sotm-audio.com

www.sotm-audio.com

Tøft når produsent skriver hva du hører.

Så for alle tusener på tusener som har trodd vi har hatt noenlunde god lyd via våre USB dacer kan tro om igjen og bare spare opp.The most noticeable improvement in sound aspect of the tX-USBx10G is that it expresses singer’s voice and textures of instruments without distortion very clearly, as if they were present at the scene. In addition, even emotions of performers who exchange music each other and where the microphone was installed and recorded can be easily revealed well.

However, it can be said that the biggest improvement of using tX-USBx10G is not only the improvement of detailed expressions, but also the ability to feel the taste of beautiful music alive.

This improvement in the sound aspect can be said to be such a significant advancement that can be divided into the era of USB audio as well as PC audio before and after the release of the tX-USBx10G. If previous tX-USB series products can be described as perfect for improving sound quality for USB audio, the tX-USBx10G, which is a remarkable step forward in technology and sound quality, is at the stage of sound perfection.

Simply saying, the tX-USBx10G is so special enough that it’s meaningless to look for an alternative to it, so it is time to forget about the old dated digital audio. -

Laster inn…

Diskusjonstråd Se tråd i gallerivisning

-

-

Laster inn…